Menu

- Home

- Shop Online

- About Us

- Portfolio

- Employment

- Blog

- Contact Us

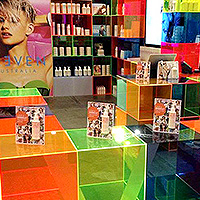

Displays made of clear acrylic are in high demand today. Commercial showrooms, retail stores, large outlets in shopping malls and many other businesses use these attractive shelves, cases, free-standing cabinets and counters to exhibit their featured brand products and other merchandise. Designers and producers of these plastic displays favor transparent acrylic or other polymer materials for manufacturing clear displays over traditional glass to prevent chipping and breaking that is dangerous and costly. Also, exhibiting cases or counters constructed of acrylic are less heavy and cumbersome than those made of glass, making them more convenient and easy to transport and deliver to different store locations or to move when rearranging the layout of a sales floor.

Selecting the Most Durable and Cost-Effective Displays for Showing Products

It is important to understand the composition, pros and cons of the different advanced synthetic materials used to manufacture fine quality, attractive displays for commercial enterprises and public display areas today. Before choosing your new displays, consider basic information like the following:

• Acrylic or Plastic. – Acrylic material, made from Methyl Methacrylate (MMA) or Poly Methyl Methacrylate (PMMA), is a thermoplastic that is transparent and frequently used as a shatter-resistant and lighter-weight substitute for glass. Its familiar trade names include Acrylite, Plexiglas, Perspex and Lucite, and all acrylic products are petroleum-based in composition. While acrylic is a type of plastic, other transparent polymers (plastics) are also used to manufacture products that would be too heavy or fragile if made of glass. However, the main problem with using injection molded plastic or Polycarbonate as a material for producing commercial displays it that these plastic surfaces can turn yellow when exposed to sunlight over time. Also, injection molded plastic may show a hazy blue surface tinge when first removed from the mold and readied for sale. Although this plastic is relatively strong, it scratches very easily, so these plastic display cases, shelves and cabinets may need frequent replacing.

• Injection Molded Acrylic or Hand-Crafted Acrylic. – Injection molded acrylic is produced when acrylic or material formed from Poly Methyl Methacrylate is injected into a mold. This type of acrylic is often used to manufacture display risers and cabinet bases. This type of acrylic never shows haziness or colors when removed from the mold and is quite strong and durable. Since less labor is required for injection molding than for hand-crafting, injection molded acrylic is the more cost-effective of the two acrylic types. If, however, you want top-tier quality acrylic for your commercial displays, hand-crafted acrylic is definitely the best choice. The hand-crafting process virtually eliminates the chance of visual flaws in the finished product. Because all joints are carefully hand-bonded with use of solvents that have the effect of melting two sections or edges together, the result gives the appearance of smooth perfection. Hand-crafted acrylic displays are also very strong and durable.

For the optimum quality acrylic displays for your business products, fine art pieces or community announcement posting board, contact the experts at Acrylic Display Industries in Knoxfield, Victoria today. These professionals will assist you in choosing the ideal type of acrylic displays to meet your specific displaying preferences and needs for your featured products, services or promotional postings.

Optimized by NetwizardSEO.com.au